Overview

At Campbell Scientific, we are committed to supporting projects that harness technology to address real-world challenges. Recently, we had the privilege of collaborating with a group of postgraduate students from the Cape Peninsula University of Technology (CPUT) in South Africa on their innovative solar crop dryer project. This initiative, part of their Postgraduate Diploma in Mechanical Engineering, aimed to tackle critical post-harvest crop drying challenges in regions with limited resources.

The student team—Jacobus TB, Classen SS, Banza Ntombe R, and Ngwadla S—under the mentorship of Mr. Deen Ebrahim, designed and developed a solar crop drying system that leverages concentrated solar power (CSP) and sand-based thermal storage. Campbell Scientific contributed to this endeavor by providing technical support and a CR1000 Measurement and Control Datalogger, which played a crucial role in monitoring the system’s thermal performance.

Challenge

In many developing regions, traditional crop drying methods—such as open-air sun drying—are inefficient, unreliable, and often result in significant crop losses. These methods are not only labor intensive but also expose crops to contamination, reducing quality and profitability for farmers.

The challenge for the CPUT student team was to design a system that not only overcomes these limitations but also remains affordable, energy-efficient, and scalable for wider use. Additionally, the system needed to use renewable energy sources to promote sustainability and reduce reliance on conventional fuels.

Solution

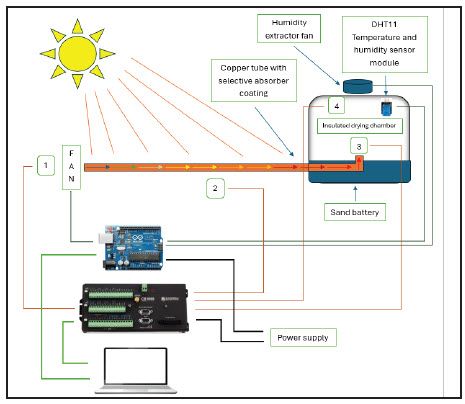

The students engineered an innovative solar crop drying system that combines cutting-edge design with practical functionality. The system features a parabolic trough collector (PTC) that focuses solar energy onto a copper tube coated with a selective absorber. Heated air from the tube passes through a sand-based thermal battery before entering the drying chamber, ensuring consistent and controlled drying conditions even after sunset.

To manage the system, the students incorporated an Arduino Uno board for airflow control, a DHT11 sensor for real-time temperature and humidity readings, and T-type thermocouples for precise thermal measurements. The CR1000 monitored temperatures at critical points within the system, ensuring reliable data for analysis and optimization.

The Campbell Scientific team provided technical assistance for setting up the data logger, enabling the students to focus on achieving optimal system performance. This collaboration ensured that the solar crop dryer met its design objectives while providing the students with invaluable hands-on experience in deploying advanced monitoring tools.

Benefits

This solar crop dryer project showcases the potential of renewable energy to address agricultural challenges in resource-limited settings. By providing a cost-effective and scalable solution, the system enhances crop preservation, reduces losses, and promotes food security. Including thermal storage allows for extended drying periods, improving efficiency and reliability compared to traditional methods.

For the students, this project was a valuable learning opportunity. They applied theoretical knowledge to a practical challenge, collaborated with industry partners, and gained experience in using advanced data collection and monitoring systems. Their dedication and ingenuity highlight the critical role of young innovators in driving sustainable solutions for global challenges.

We are proud to have supported these students in their journey and look forward to seeing their work inspire further advancements in sustainable agriculture. This project serves as a testament to the power of collaboration and innovation in building a better future.

Note: Currently, the newest version in our CR1000 datalogger series is the CR1000Xe Measurement and Control Datalogger.

Resumen de casos de estudio

Aplicaciones

Crop preservation for food securityUbicación

Cape Town, South AfricaProductos utilizados

CR1000Organizaciones participantes

Cape Peninsula University of Technology (CPUT)Parámetros medidos

Temperature, humidityView the PDF