This product is not available for new orders. We recommend ordering: 03101.

| Services Available |

|---|

Overview

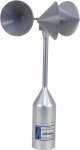

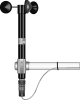

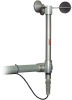

The 014A, manufactured by Met One, is a three-cup anemometer that monitors wind speed for the range of 0 to 45 m/s with a threshold of 0.45 m/s. It connects directly to a Campbell Scientific datalogger, which measures the 014A's pulse signal and converts the signal to engineering units (mph, m/s, knots).

Read MoreBenefits and Features

- Ideal for applications that do not require wind direction measurements

- Sealed magnetic reed switch

- Designed for continuous, long term, unattended operation in adverse conditions

- Standard aluminum cup assembly has a distance constant of less than 4.5 m

- For greater sensitivity, an optional LEXAN cup assembly has a distance constant of less than 1.5 m

Images

Detailed Description

The 014A is constructed of corrosion-resistant, stainless-steel and anodized aluminum. It's three-cup anemometer assembly contains a sealed magnetic reed switch. Rotation of the cupwheel produces a pulse that is directly proportional to wind speed.

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Dataloggers

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR1000Xe | ||

| CR300 (retired) | ||

| CR3000 (retired) | ||

| CR310 | ||

| CR350 | ||

| CR6 | ||

| CR800 (retired) | ||

| CR850 (retired) |

Additional Compatibility Information

Mounting

The 014A attaches to a Campbell Scientific crossarm using a 1049 Nu-Rail fitting or CM220 Right Angle Mounting Bracket. It also can be attached to the top of our CM110, CM115, and CM120 stainless-steel tripods using the CM216 Sensor Mounting Kit.

Data Logger Considerations

The 014A uses one pulse count channel on the data logger.

Programming

The 014A is read by the PulseCount Instruction in CRBasic and by Instruction 3 (Pulse Count) in Edlog. Wind speed measurements can be taken and processed with any of the data loggers.

Specifications

| Sensor | 3-cup anemometer |

| Measurement Description | Wind speed |

| Range | 0 to 45 m/s (0 to 100 mph) |

| Starting Threshold | 0.45 m/s (1.0 mph) |

| Accuracy | 0.11 m/s (0.25 mph) or 1.5% |

| Contact Rating | 10 mA (maximum) |

| Operating Temperature Range | -50° to +70°C |

| Distance Constant |

|

| Cable Description | Quick-connect connector with vinyl jacketed, shielded cable |

| Radius | 10.4 cm (4.1 in.) |

| Height | 34.8 cm (13.7 in.) |

| Sensor Weight | 318 g (11 oz) |

| Cable Weight | 140 g (5 oz) per 3 m (10 ft) length |

Documents

Product Brochures

Manuals

Frequently Asked Questions

Number of FAQs related to 014A-L: 1

-

The 014A-L sensors use magnets spinning over a mechanical reed switch to sense wind speed. Eventually the mechanical reed switch will fail and will need to be replaced. Replace both the bearings and the reed switch at the same time. For details on replacing bearings and the reed switch, see Appendix C of the instruction manual.

Casos de estudio

North Dakota agriculture ranks high in the nation’s crop production: No. 1 in durum and......read more

In a country as large as Argentina, monitoring growing conditions in different agricultural regions is......read more